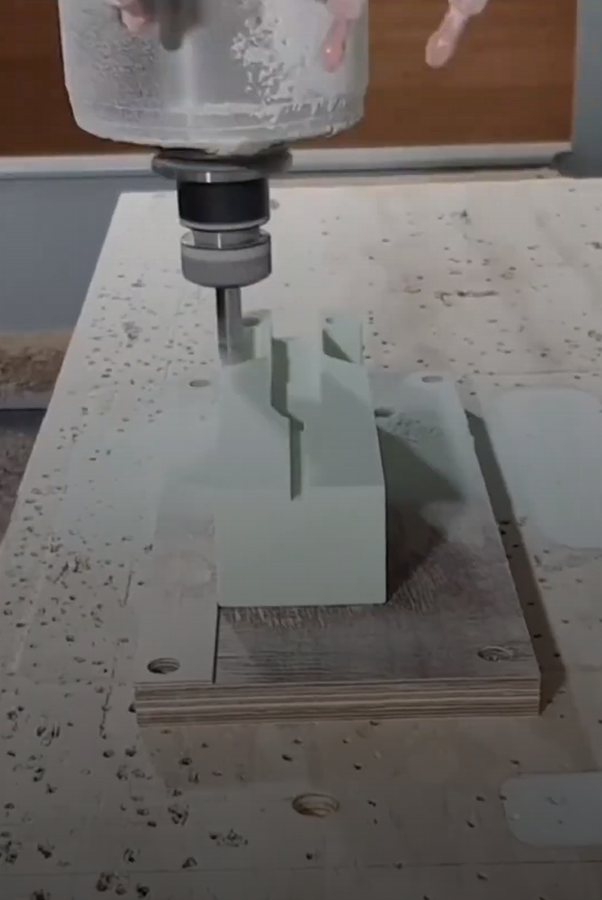

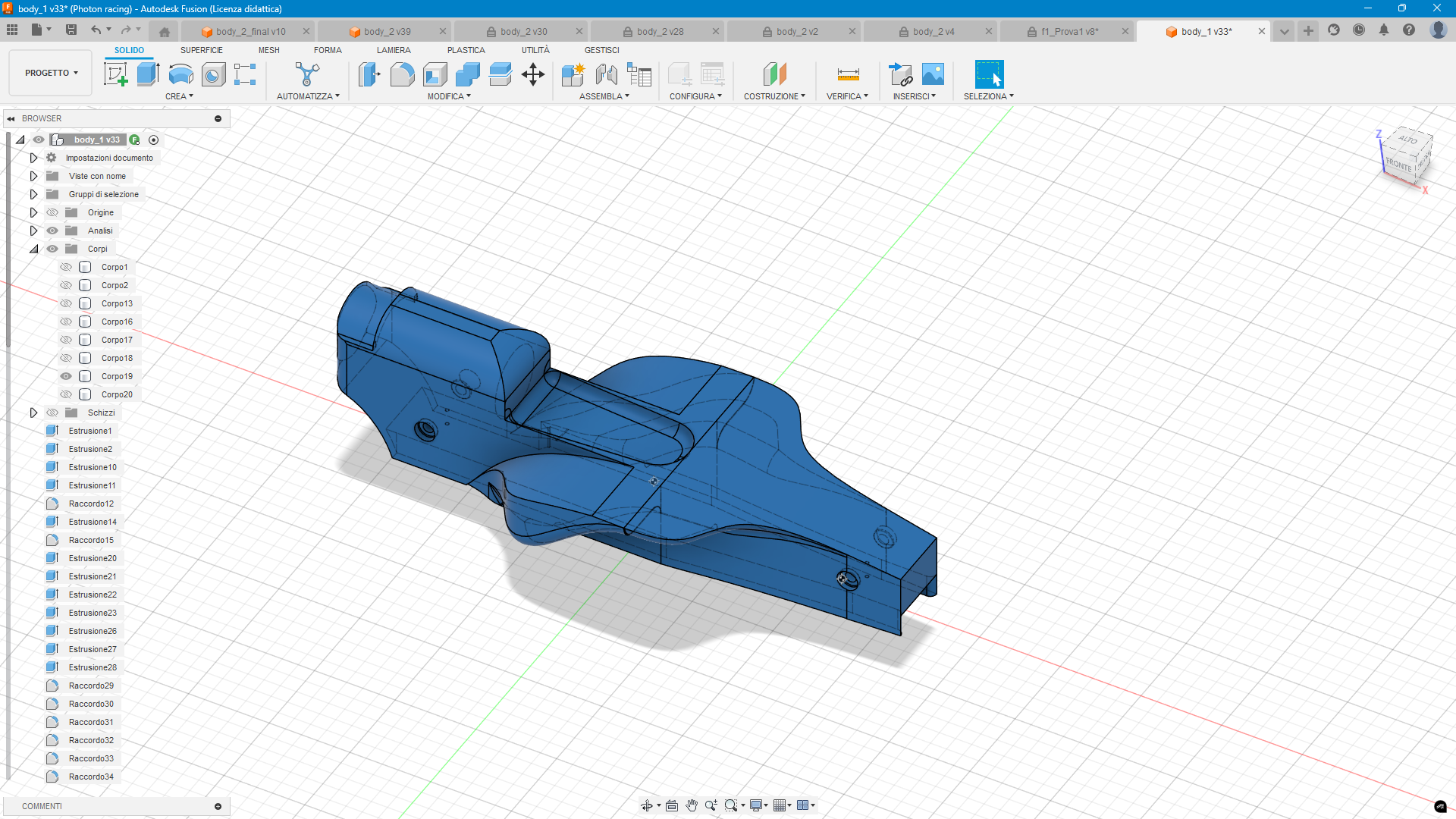

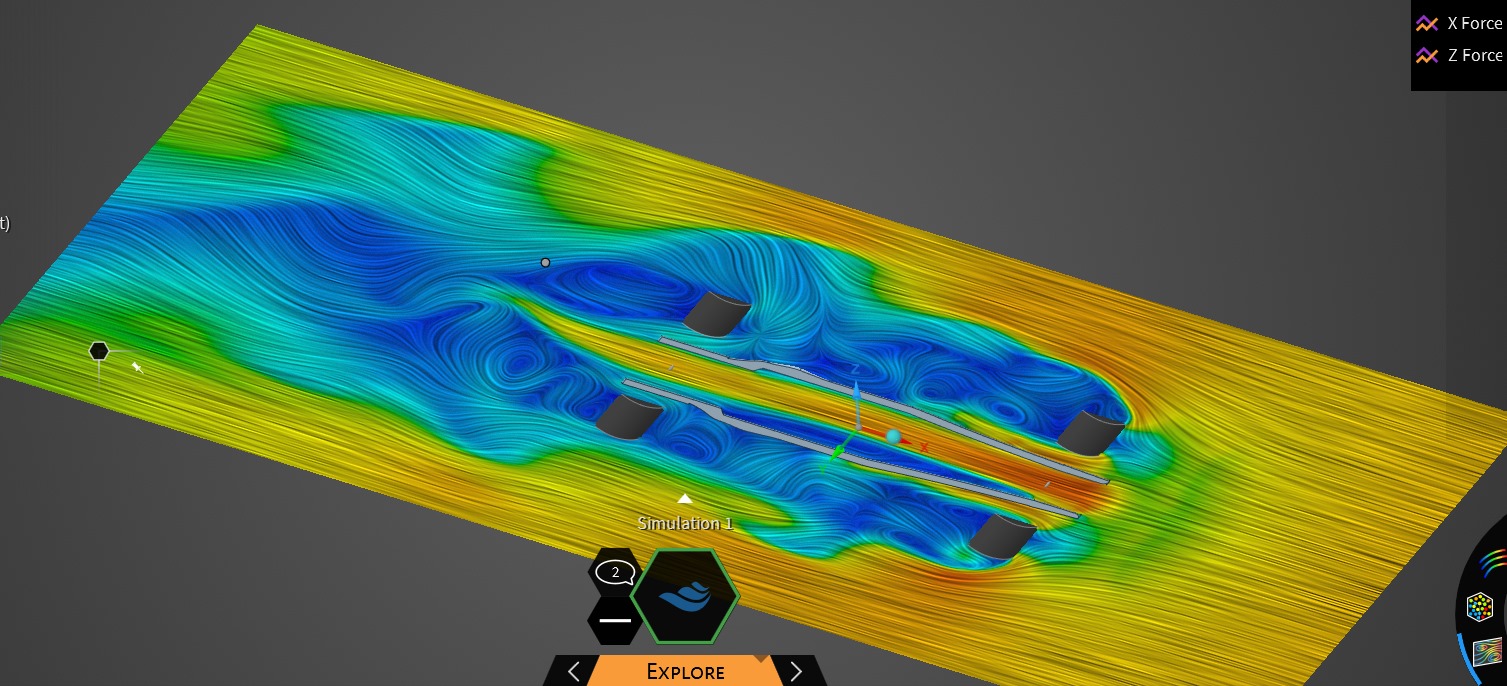

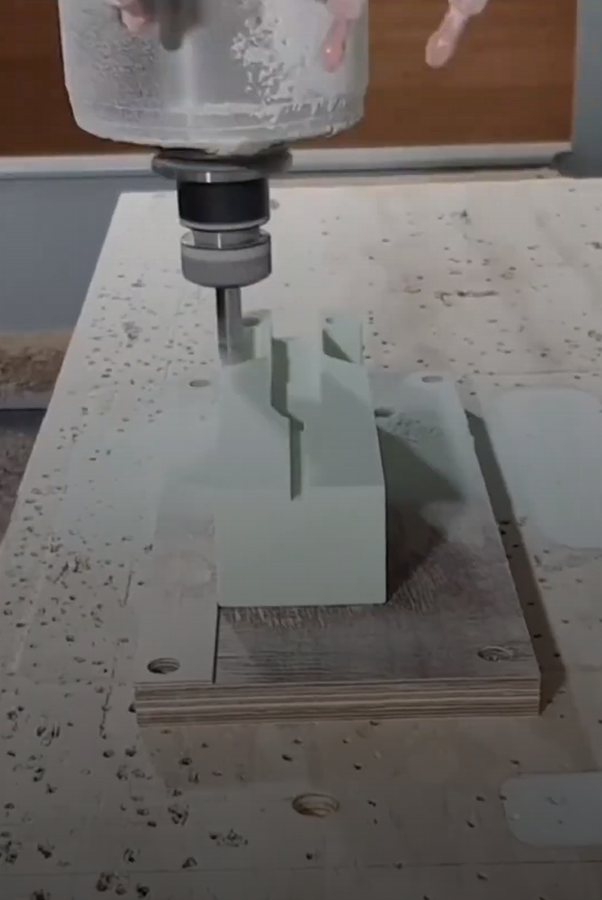

Manifacturing

Thanks to our partner Famar, we were able to craft our

body at Ilma. We started from the block provided, and

by precisely milling it, we took off materials giving life to

our prototype. Since we didn’t have access to five axis

machinery, we had to first mill the bottom part of the

body, then create a support structure to keep it stable

and finally mill also its upper part. In the process were

used drills of different sizes, from larger ones to clear up

the exceeding material to the smallest one they had, 3

mm, to refine the car. We also made our own tether

guide lines, turning them out of aluminum, so that we

could secure them by screw threads

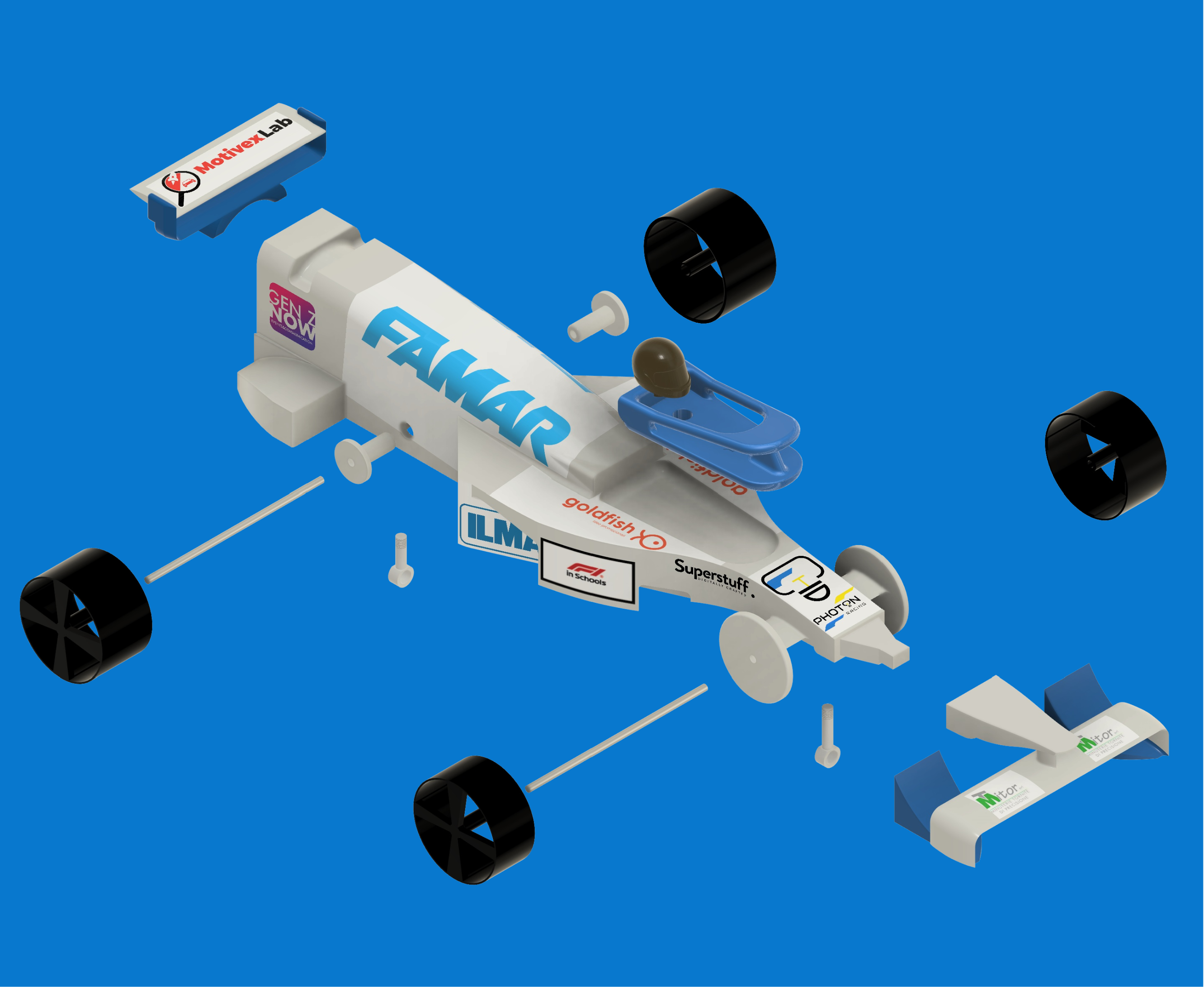

Apart from the body and the tether guide lines every

other component, that is the wings, the halo and the

support structures, is 3D-printed. We did a bit of

research to find the best material to use, it turned out

that PLA was one of the best options in terms of

availability, costs and additionally it allows for easy and

perfectly fitted assembly by slightly heating the parts.

For the axles we used the ones we were provided with,

having pretty low friction and being really stable